Water in Textile and Apparel Supply Chains

What Can We Learn About Water Management in the Textile and Apparel Industry

As fashion brands begin to consider their corporate social responsibility metrics and goals, the demand for sustainable fashion and transparency continues to rise. Though there are some critical reviews of the sincerity and level of investment some brands are making to accomplish these claims and communicated goals, the fashion industry and its players have brought considerable attention to water usage in apparel and textile production. For those brands and retailers serious about sustainability, careful review of water usage and waste impacted by textile and apparel supply chains, critical & positive sustainability impacts can be achieved.

What water metrics and targets matter in textile and apparel sustainability?

The World Wildlife Fund considers water in the textile industry in three key components: quantity (usage), quality (pollution), and governance (regulations). Each of these components plays a role in the overall impacts on the environment and communities around the world. When considering water stewardship and scarcity, the way supply chains and consumers interact with water have great impacts on usage, pollution, and regulations.

The fashion industry requires intensive amounts of water to grow, produce, finish, and maintain its products. Annually, the industry consumes 93 million cubic meters of water. To put it into perspective, to produce a single cotton tee-shirt, the manufacturing process can require up to 2,700 liters of water, an equivalent to 9 bathtubs for each shirt. However, this number does not include the amount of water used by the end user to wash the garment. This ambiguity when including the entire life cycle of a product can create issues within benchmarking and regulating water usage.

While determining the exact water usage in a product’s life cycle can be quite difficult, the industry must consider water scarcity. Agriculture of cotton consumes 2.8% of global water consumption, yet the crop is grown in water stressed regions across the world. In India it is estimated that for every 1kg of cotton produced, 22,500 liters of water is consumed. As a water stressed country, India contains roughly 16% of the world’s population but only has access to 4% of the world’s fresh water. Therefore, water is being used for a water intensive production process in a region where water is scarce.

Water usage and scarcity is a great cause for concern, yet, the fashion industry must think even broader in terms of its impact on water. Pollution caused by pesticides, dyes, chemicals, and laundering is another issue attributed to the textile and apparel industry. With over 200,000 different chemicals used throughout textile and apparel supply chains, the lack of proper waste water management by factories, use of pesticides in agriculture, and microplastics released by laundering all contribute to the pollution of freshwater and oceans across the globe. This perpetuates the water scarcity issue, as fresh water in water stressed areas may not be safe for drinking.

Despite this detrimental impact, approximately only one in ten fashion companies are considering their impacts on the environment through textile production pollution and usage. As policies for water usage are more recently being implemented, regulations on water pollutants are a bit more established. The EPA currently has had regulations set in place since the 1970s for various chemicals and pollutants produced by the textile industry in the U.S. However, regulations are beginning to take form in nations where textiles are more heavily produced. In India, some portions of the country have set in place zero liquid discharge (ZLD) regulations that require manufacturers to filter their waste water to eliminate, but in most cases limit, pollutants. Still, further regulations must be established, monitored, and enforced, as water scarcity and pollution issues continue to persist.

Our solution is also supplemented with live streams and customer education initiatives to help customers learn how to avoid fraudulent activity when purchasing diamonds, all of which will provide a superior digital user experience.

Why is it difficult to estimate water impact broadly and across the supply chain?

Within apparel production, there are many levels of the supply chain that need to be considered. In order for water usage and pollutants to be traced back to a specific product, brands need to take into account how each process within an item’s production can impact these figures.

Different fabrics and textiles experience unique steps, which can impact metrics and data on water. For example, to make a cotton tee shirt, the cotton must be grown, collected, cleaned, spun, knit/woven, cut, sewn, finished, and washed. Each component of this supply chain contributes to the water usage and pollutants associated with the production of any textile or apparel product. Determining the exact emissions and usage of water the fashion industry is responsible for can be estimated, but finding the exact data and metrics can be daunting. Though brands can use data collected by their manufacturers and farmers, those figures might not include the data of water used in the full life cycle of each garment.

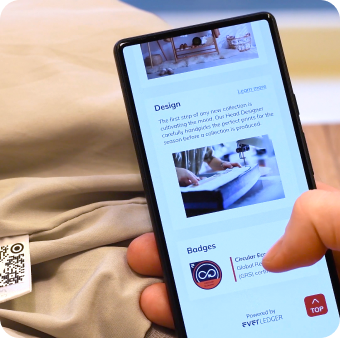

This challenge is not dissimilar to some of the early challenges of GHG measuring, tracking and reporting. While GHG data has improved, it is still rare for brands to track their GHG through the supply chain back to source because of the complexities of the supply chain, the multiple forms of reporting formats, and the challenges of calculations across all the actors. This is one reason that Everledger has worked to establish a layer of quantitative data capture on top of block chain layer that is tracking the chain of custody details. This allows for not only GHG quantitative data and associated evidence, but also the future capture of water metrics.

Still measuring and understanding the extent of the challenge is only the first step. Solutions have to be applied to use less, prevent polluted discharge, and avoid stressing water sources human and ecosystems need to survive and flourish.

What industry solutions have been innovated to address water issues?

While we have discussed the negative impacts the fashion industry has had on water quality and usage, it is important to turn our focus to solutions. Fashion manufacturers and brands are discovering new ways to limit their water impacts through innovative techniques and processes.

As discussed above, one major contributor in fashion supply chains to water outcomes is agriculture. Through selective fiber production, organic farming, and regenerative agriculture, natural textile production can become more sustainable and responsible. With supply chains supporting farmers to diversify crops and farm less water intensive fibers, water usage for a crop yield can decrease. Furthermore, regenerative agriculture’s goal is to “close the carbon cycle, and build soil, health and crop resilience,” as well as increase water holding capacity in order to reverse the effects of climate change. Through these practices, farmers can use less water and ensure a more sustainable future for their land. Additionally, the implementation of organic farming should decrease use of toxic pesticides and chemicals, thus preventing polluted runoff into the water table as well as keeping many nutrients in the soil to maintain soil health.

Another contributing factor to water sustainability is decreasing usage in the dyeing and finishing processes of apparel production. For example, one of the most water intensive steps of denim production is dyeing and finishing. To resolve this issue, Levi’s has created the Water<LessTM Program to limit the use of water in their manufacturing processes through innovating new dyeing and finishing techniques. Through these innovative processes, Levi’s has discovered that they can reduce their water consumption by up to 96%, and they have been able to recycle more than 1.5 billion liters of water through their new practices.

Brands, manufacturers, and farmers can enact change in their water usage and pollution through innovative practices and technologies. However, to improve the outcomes attributed to the consumer use stage of a product’s life cycle, consumers themselves must also be conscious of their consumption. Fashion shoppers need to consider their use of water and emissions of microplastics in laundering their clothes, as their part in improving water scarcity and pollution is just as crucial as the producers’. Therefore, in order for true change to occur, brands, manufacturers, farmers, and consumers must all work together.

What can you do to support water sustainability in textile and apparel supply chains?

Through Everledger’s impacts on supply chain transparency, we have opened the door to aid in the connection of each component of sustainable production. Through technology, Everledger can play a role in pulling back the curtain of ambiguity associated with water usage and pollutant metrics in the fashion industry. Everledger can provide brands, manufacturers, and farmers with the tools they need to track their water data, benchmark their progress, and determine where improvements can be made throughout each step of the supply chain.

Not only does Everledger support tracking this data, but also can support linking to the changemakers supporting the impacts around the world. With our GHG product, we have created plug in options for carbon offset partners. We foresee that we can begin to engage with players internationally to connect them to those supporting water rehabilitation projects.

There could also be opportunities to use our consumer engagement to influence behavior towards more responsible actions. In our US Department of Energy grant, we created a proof of concept to incentivize consumers to drop off their batteries in specific locations. Why couldn’t we begin similar campaigns to drive change at home to wash clothes responsibly? Some retailers, such as Thredup, have begun consumer engagement campaigns to directly address this issue, but with Everledger’s advanced technology and unique platforms, we can further aid in the goal to limit global water usage.